Newport

Technology

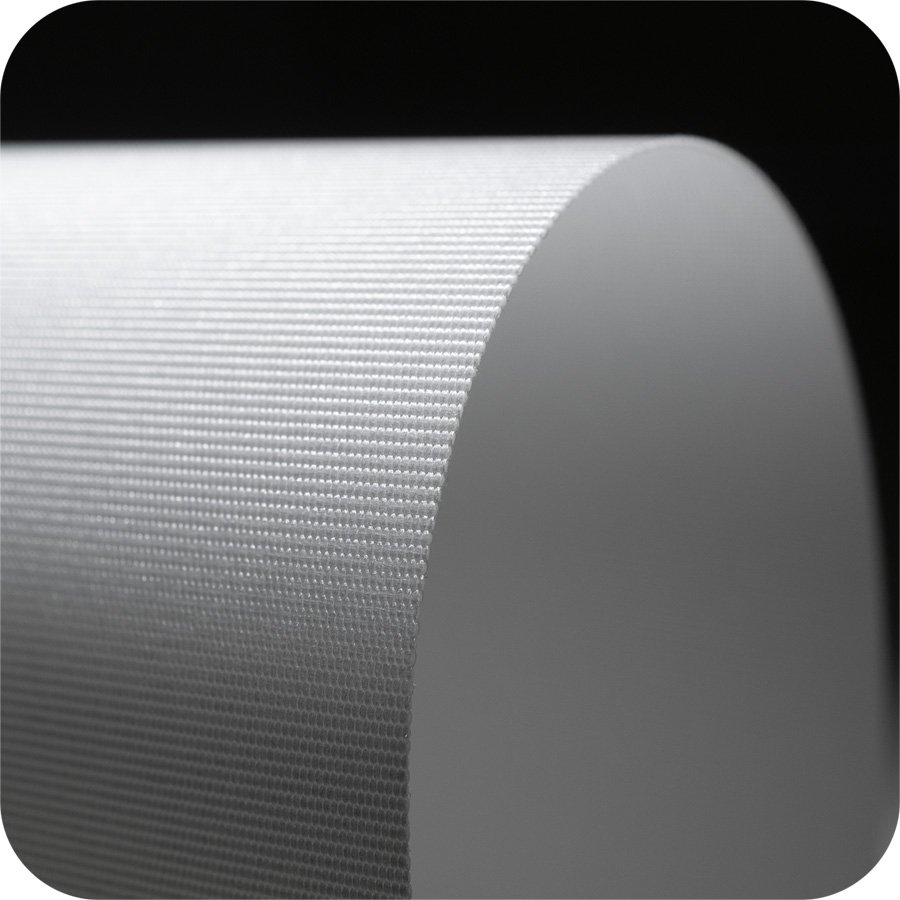

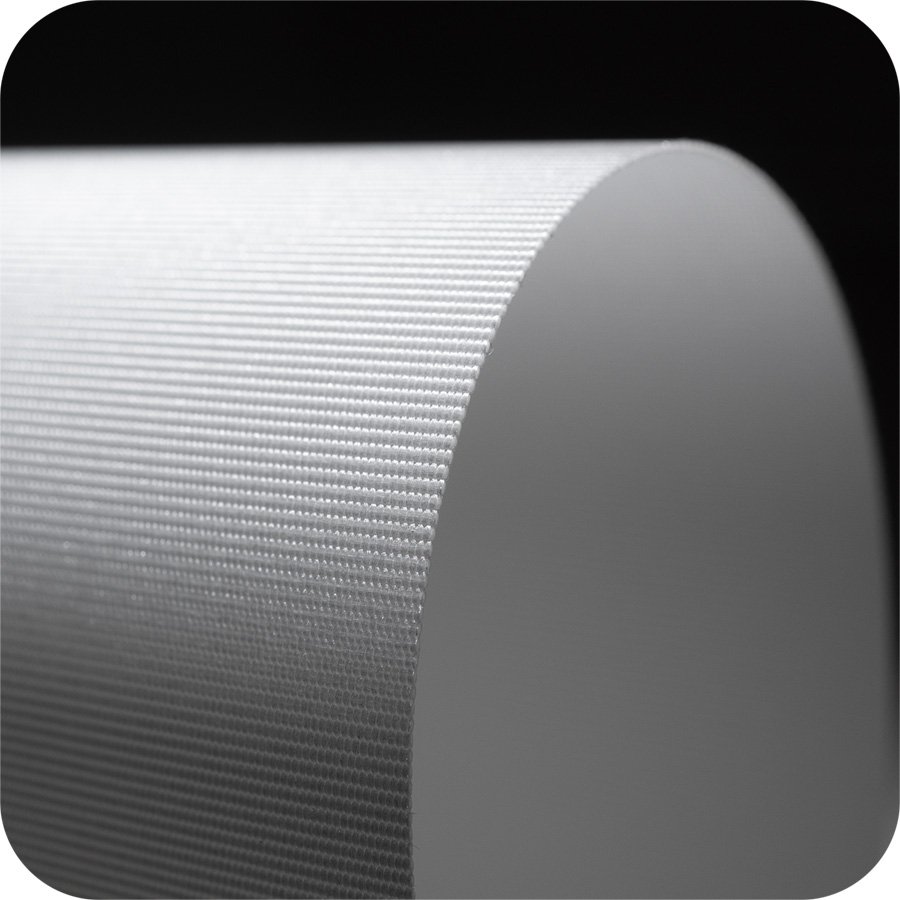

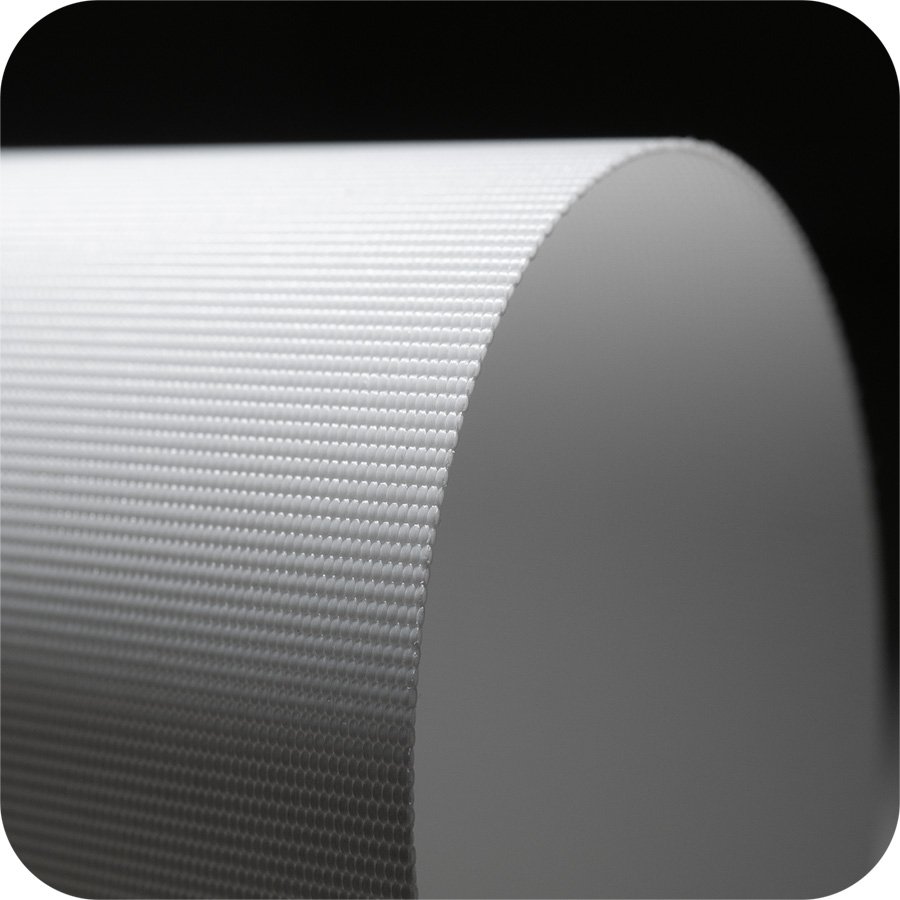

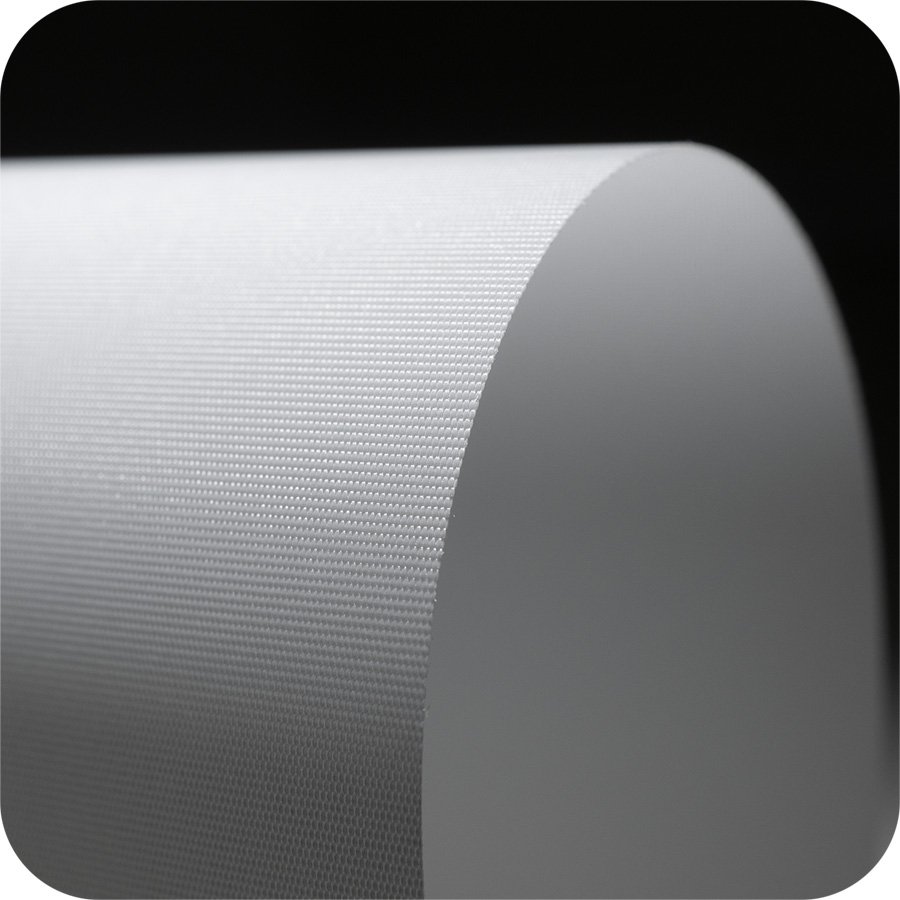

Newport High-End Sailcloth features three distinct construction types: All Purpose, Low Aspect, and Pro Radial. Crafted with precision at our bluesign® certified facility, Newport weaves utilize the finest sailcloth, fiber available — Challenge Fiber 104.

This premier product line embodies the cutting-edge research and development advancements that Challenge has gained from producing the renowned Marblehead High and Low Aspect sails. Newport sails are engineered with strong 1% fill numbers and durable denier combinations for All Purpose and Low Aspect applications, alongside exceptional warp performance for Pro Radial designs.

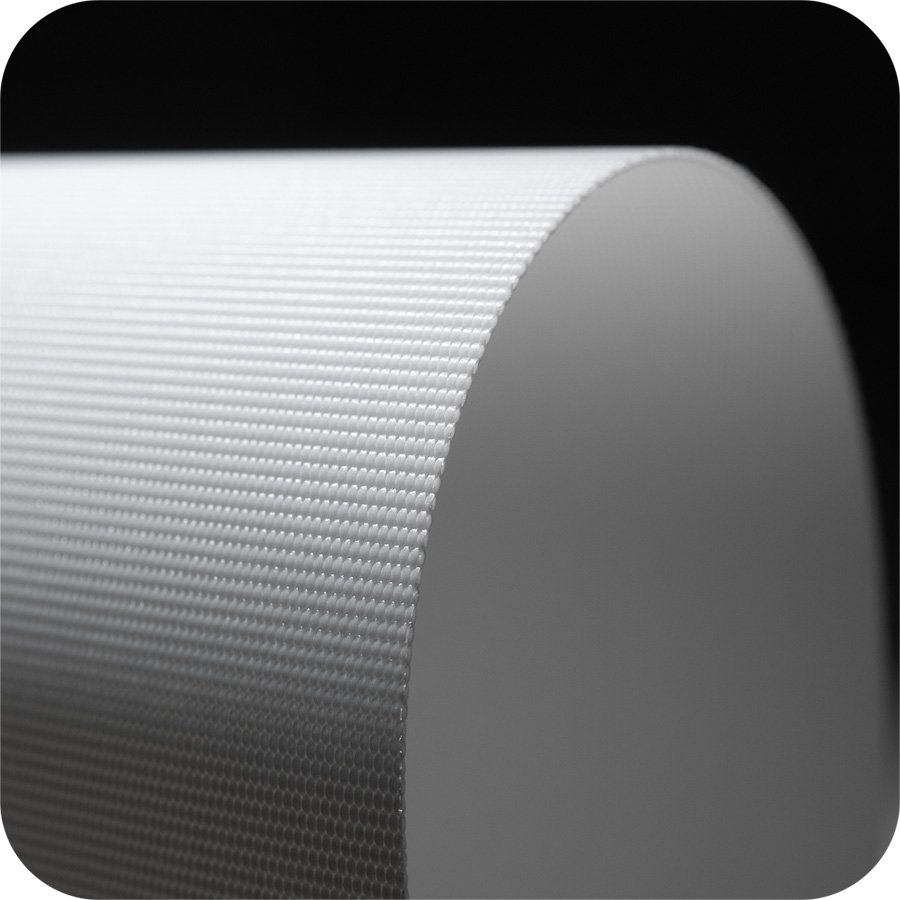

Challenge Fiber 104 stands out by accommodating more fibers per inch compared to competing sailcloth, resulting in tight weaves that deliver excellent shape retention, unmatched durability, and superior UV protection.

For sailors seeking high-quality performance and reliability, the Newport collection offers unparalleled craftsmanship and satisfaction. Choose your ideal Newport sail and experience the perfect blend of trust, quality, and performance on the water

-

The Challenge Sailcloth Newport brand is the most recent addition to our highest end sailcloth.

Newport is a complete product line with three main construction types: All Purpose, Low Aspect and Pro Radial. Newport is produced using the best sailcloth fiber available; Challenge Fiber 104.

This new product line combines all of the R&D Technology which Challenge has learned from the production of famous brands (such as Marblehead, Warp-Drive and High Mass Fiber Weaves). Challenge has designed constructions with very strong fill 1% numbers, rugged denier combinations for AP applications, and strong radial performance in Newport PR. Fiber 104 can pack more fibers in a sail than competing sailcloth. Challenge has developed a mechanical advantage.

The results are tight weaves, excellent shape holding, rugged durability and high UV protection. Sailors who need a high quality sail can choose from one of the three Newport lines for trust, quality and fantastic satisfaction with their sail.

-

Newport AP for Performance Cruising Sails

Newport LA for Low Aspect Traditional Sails

Newport Pro Radial for performance cruising Tri Radial

Newport Black for technical-appearance cruising sails

Newport Classic for traditional tanbark and cream sails

Newport Tall Ships for square rig yachs

Newport Color for vibrant racing sailboats

FIber104 Constructions

UV Finish

Durable medium-firm finish

-

Newport has over 50 different fabric weights, which far exceed the space on this website block.

Please reach out to your sailmaker for the performance graph on the individual fabric needed for your yacht!

Newport All Purpose

Extremely Strong Fill yarns to handle high leach loads on sails.

Robust constructions ranging from Higher Aspect styles to more well rounded all purpose for all kinds of sails

D5.45

D5.93

D6.45

D7.45

D7.95

D8.45

D9.45

D10.95

Newport All Purpose

| Fabric ID |

Description |

Yarn Denier Warp Fill |

Fabric Width in cm |

| D5.45 | 5.45 Newport All Purpose | 200 350 | 54 137 |

| D5.93 | 5.93 Newport All Purpose | 150 350 | 54 137 |

| D6.45 | 6.45 Newport All Purpose | 220 440 | 54 137 |

| D7.45 | 7.45 Newport All Purpose | 275 500 | 54 137 |

| D7.95 | 7.95 Newport All Purpose | 275 750 | 54 137 |

| D8.45 | 8.45 Newport All Purpose | 350 840 | 54 137 |

| D9.45 | 9.45 Newport All Purpose | 350 1000 | 54 137 |

| D10.95 | 10.95 Newport All Purpose | 440 1300 | 54 137 |

| D12.95 | 12.95 Newport All Purpose | 500 1800 | 54 137 |

Newport Low Aspect

Low Aspect constructions designed for more traditional boats and rigs with longer “J” and “E” measurements.

Balanced tight weave for increased bias strength and excellent recovery

D4.93

D5.53

D6.53

D7.03

D8.03

D9.03

D10.53

Newport Low Aspect

| Fabric ID |

Description |

Yarn Denier Warp Fill |

Fabric Width in cm |

| D4.93 | 4.93 Newport Low Aspect | 150 250 | 54 137 |

| D5.53 | 5.53 Newport Low Aspect | 250 300 | 54 137 |

| D6.53 | 6.53 Newport Low Aspect | 250 370 | 54 137 |

| D7.03 | 7.03 Newport Low Aspect | 250 420 | 54 137 |

| D8.03 | 8.03 Newport Low Aspect | 300 500 | 54 137 |

| D9.03 | 9.03 Newport Low Aspect | 300 700 | 54 137 |

| D10.53 | 10.53 Newport Low Aspect | 350 840 | 54 137 |

| D11.93 | 11.93 Newport Low Aspect | 500 1300 | 54 137 |

Newport Pro Radial

Large warp yarns to give low stretch in the warp direction and provide great durability and UV protection

Tight weaves, using a balanced construction for good 1% numbers in Warp, bias, and fill.

D5.1

D6.1

D7.1

D8.1

D9.1

D10.1

Newport Pro Radial

| Fabric ID |

Description |

Yarn Denier Warp Fill |

Fabric Width in cm |

| D5.1 | 5.1 Newport Pro Radial | 150 250 | 54 137 |

| D6.1 | 6.1 Newport Pro Radial | 250 350 | 54 137 |

| D7.1 | 7.1 Newport Pro Radial | 350 440 | 54 137 |

| D8.1 | 8.1 Newport Pro Radial | 440 520 | 54 137 |

| D9.1 | 9.1 Newport Pro Radial | 500 750 | 54 137 |

| D10.1 | 10.1 Newport Pro Radial, | 600 840 | 54 137 |

Quality Sailing Constructions

Sails designed with Newport AP generate fast, durable and beautiful sails.

The Black Pearl

High Performance

Newport Tall Ships

Designed for demanding large yachts, each Newport Tall Ships construction is woven with tough 1000d warp fibers and rugged fill fibers. This combination gives excellent tearing strength as well as UV and Abrasion Resistance. The standard finish has a softer hand feel specifically designed for ease of sail handling. Challenge also has a wide variety of custom produced Tall Ships styles that have been made for special projects. Please inquire about custom styles for unique boats.

Vibrant Race Colors

Newport is produced in over a dozen standard colors, and custom colors by many sailmaking groups.

The Future is Now, and it Can’t Wait.

The legacy of Challenge Sailcloth spans four generations in the sailing textile industry. In 1917, our family founded Howe and Bainbridge, one of the first sailcloth companies in the USA. In the 1930s, DuPont® invented synthetic polyester and nylon fibers which we used to create the first Cordura® nylon mainsail cloth. Moving from tar-impregnated cotton sails to technical synthetic textiles started a new era of sailboat racing and innovation. We’ve been leaders at the forefront of textile innovation for over 100 years. Looking forward, our focus is entirely on sustainability within the textile industry.

In 2020, Challenge Sailcloth launched a new company called Challenge Outdoor, spearheaded by world champion sailor and technical textiles expert, Hale Walcoff. Hale had a vision to produce light, durable, and UV resistant materials for the outdoor sports industry using 100% recycled polyester. He wanted to produce fabrics that were best in class for the industry while being environmentally friendly. Challenge Outdoor is dedicated to reducing real-world carbon emissions and promoting clean textile technology. As outdoor enthusiasts, it is our duty to tackle the climate crisis.

This project would not have been possible as recently as five years ago, because recycled and natural component manufacturers had not achieved the performance levels required in strenuous and demanding outdoor sports. Thankfully, the global community demanded green tech, and the investment followed. Moving full speed ahead, our development efforts will be focused on sustainable innovation across our product lines. This is our new race against the clock and a challenge to the industry. Solving the climate crisis requires world-wide collaboration and we welcome you to get on board.

Sustainability Starts with You

Energy-Efficient Manufacturing

Our textiles are produced at eco-friendly facilities powered by hydroelectric energy.

Our innovative manufacturing system eliminates expensive and energy intensive drying ovens, hot rooms for curing, and many other processes needed to laminate Nylon and Polyester with solvent-based adhesive.

We maintain stock in both the U.S. and Asia for better efficiency with our manufacturing partners and brands.