Code-Tec

Technology

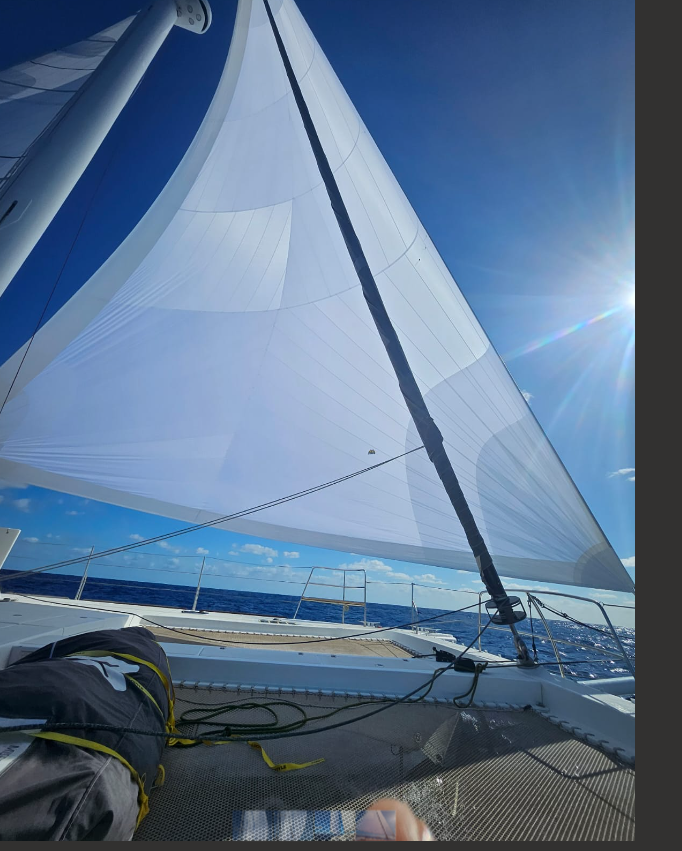

Challenge is excited to announce Code-Tec, a series of new fabrics specifically designed for the new generation of asymmetric and reaching sails used on modern racing and cruising designs. As off-the-wind sails designed for tighter sailing angles continue to evolve with the new structured luff and cableless Code sail designs, Challenge has developed this unique new range of fabrics to meet the performance requirements for this new generation of sails.

Code-Tec uses high tenacity fibers and proprietary immersion coating chemistry to make a high performance but durable Code sail fabric which boasts low stretch, high tear strength and the ability to withstand repeated furls on modern roller furling storage systems. Code-Tec has tear and breaking strength not seen to date in polyester spinnaker fabrics.

-

A breakthrough in asymmetric fabric technology.

Double-beam matrix ripstop pattern for rugged durability.

Leading edge kitesurf finish, with outstanding adhesion and life performance compared to spinnaker cloth or traditional dacron.

Code-Tec has tear and breaking strength not seen to date in polyester spinnaker fabrics.

New immersion-coating technology.

Proprietary chemistry for high performance and durability.

Sun-Tec UV roller furling available for UV resistance comparable to much heavier fabrics

-

Code55p - 1.2 SM oz / 52gsm

Code95p - 1.9 SM oz / 81 gsm

Code135p - 3.1 SM oz / 132 gsm

Code170px - 3.9 SM oz / 170 gsm

Code195UPE - 4.5 Sm oz / 195 gsm

Code245UPE - 5.7 SM oz / 245 gsm

-

XRP sport enables sailmakers to build performance race sails with all polyester constructions.

The efficient fiber laydowns allow high performance without the use of exotic fibers such as Aramids and Carbon

CODE55P

CODE95P

CODE135P

CODE155P

CODEX170

CODE195UPE

CODE245UPE

Code-Tec

| Fabric ID |

Insert DPI Warp X / 1.5" |

Taffeta Color |

Film |

Weight SM oz gsm |

Width in cm |

| WOVENS | |||||

| CODE55P | – – – – | White | – – | 1.2 51 | 60 150 |

| CODE95P | – – – – | White | – – | 1.9 81 | 60 150 |

| CODE135P | – – – – | White | – – | 3.1 132 | 60 150 |

| CODE155P | – – – – | White | – – | 3.4 146 | 60 150 |

| LAMINATES | |||||

| CODEX170 | – – 1,000 / 45° | White | 0.50 | 3.9 170 | 60 150 |

| CODE195UPE | 6,000 1,000 / 22° | White | 0.50 | 4.5 195 | 60 150 |

| CODE245UPE | 12,000 1,000 / 22° | White | 0.50 | 5.7 245 | 60 150 |

A Revolutionary Code

Code Tec has super strong Ultra PE reinforced luff panels, in combination with ultralite Code55p body fabric. Sailmakers can make a cable free code zero with the most durable material on the market.

The Future is Now, and it Can’t Wait.

The legacy of Challenge Sailcloth spans four generations in the sailing textile industry. In 1917, our family founded Howe and Bainbridge, one of the first sailcloth companies in the USA. In the 1930s, DuPont® invented synthetic polyester and nylon fibers which we used to create the first Cordura® nylon mainsail cloth. Moving from tar-impregnated cotton sails to technical synthetic textiles started a new era of sailboat racing and innovation. We’ve been leaders at the forefront of textile innovation for over 100 years. Looking forward, our focus is entirely on sustainability within the textile industry.

In 2020, Challenge Sailcloth launched a new company called Challenge Outdoor, spearheaded by world champion sailor and technical textiles expert, Hale Walcoff. Hale had a vision to produce light, durable, and UV resistant materials for the outdoor sports industry using 100% recycled polyester. He wanted to produce fabrics that were best in class for the industry while being environmentally friendly. Challenge Outdoor is dedicated to reducing real-world carbon emissions and promoting clean textile technology. As outdoor enthusiasts, it is our duty to tackle the climate crisis.

This project would not have been possible as recently as five years ago, because recycled and natural component manufacturers had not achieved the performance levels required in strenuous and demanding outdoor sports. Thankfully, the global community demanded green tech, and the investment followed. Moving full speed ahead, our development efforts will be focused on sustainable innovation across our product lines. This is our new race against the clock and a challenge to the industry. Solving the climate crisis requires world-wide collaboration and we welcome you to get on board.

Sustainability Starts with You

Energy-Efficient Manufacturing

Our textiles are produced at eco-friendly facilities powered by hydroelectric energy.

Our innovative manufacturing system eliminates expensive and energy intensive drying ovens, hot rooms for curing, and many other processes needed to laminate Nylon and Polyester with solvent-based adhesive.

We maintain stock in both the U.S. and Asia for better efficiency with our manufacturing partners and brands.